Top Notch Cane Sugar Processing Chemicals: Trusted and Safe

Top Notch Cane Sugar Processing Chemicals: Trusted and Safe

Blog Article

Maximizar Rendimientos Y Minimizar Costos: Estrategias Avanzadas Para La Optimización Química Del Procesamiento De Azúcar De Caña

In the world of cane sugar processing, the search of optimizing returns while concurrently lessening costs stands as a powerful obstacle that requires a tactical mix of innovative chemical optimization techniques. The ins and outs of this undertaking look into the core of performance, where every component of the process plays an important duty in attaining optimal results. By checking out the details of chemical analysis, enzyme usage, pH control, filtering, and purification approaches, a landscape abundant with possibilities for enhancement and innovation emerges. In the middle of this complex internet of approaches exists the assurance of opening untapped potential and revolutionizing the very essence of sugar production. Cane Sugar Processing Chemicals.

Chemical Analysis for Efficiency

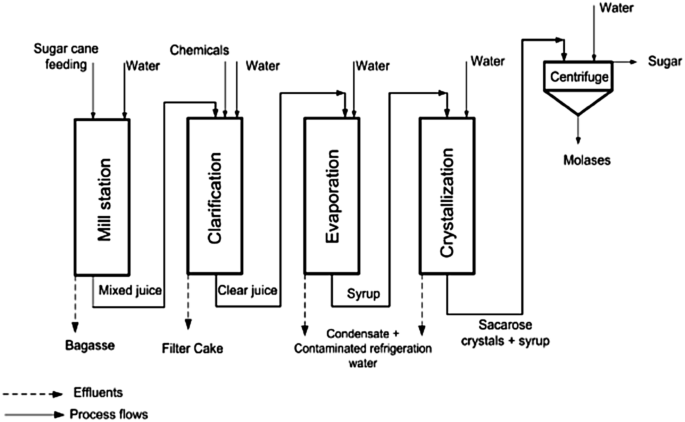

Chemical evaluation plays a critical role in enhancing the effectiveness of sugar cane handling by giving important insights into the make-up and residential or commercial properties of the raw products. By carrying out in-depth chemical analyses on sugar walking stick examples, processors can identify the exact focus of sucrose, glucose, fructose, and various other elements present in the raw product. This info is vital for maximizing the different stages of the sugar walking cane processing chain, from crushing to condensation.

Furthermore, chemical evaluation allows processors to determine impurities such as organic acids, proteins, and minerals that can influence the quality and return of the final sugar item. By measuring these contaminations, processors can carry out targeted methods to remove or minimize their impacts, inevitably enhancing the total efficiency of the handling plant.

Additionally, chemical evaluation facilitates the monitoring of process criteria such as pH, temperature, and thickness, permitting processors to make real-time modifications to make certain optimal problems for sugar removal and crystallization. Generally, a comprehensive understanding of the chemical structure of sugar walking cane is important for maximizing yields, lessening prices, and maintaining high product high quality in the sugar manufacturing sector.

Enzyme Use for Increased Returns

With a strategic technique to enzyme application, sugar walking stick cpus can significantly improve their returns while maintaining functional performance in the production process. Enzymes play a critical role in sugar walking stick handling by breaking down complicated carbs right into simpler sugars, therefore boosting the total sugar extraction effectiveness. By including details enzymes tailored to target the different elements of sugar walking cane, such as cellulose and hemicellulose, cpus can improve the release of sugars during extraction.

Enzyme application offers the advantage of optimizing sugar returns from the raw material while decreasing the power and resources needed for handling. This results in a much more sustainable and economical manufacturing procedure. In addition, enzymes can aid in decreasing processing time and boosting the general high quality of the sugar item. With cautious choice and application of enzymes, sugar walking stick cpus can enhance their procedures to accomplish higher yields and success.

Ph Control for Optimum Handling

Enzyme use for boosted yields in sugar cane handling lays the structure for attending to the vital aspect of pH control for optimal handling effectiveness. Maintaining the see this page appropriate pH degree throughout different stages of sugar walking cane handling is vital for making the most of yields and decreasing expenses. pH control is particularly critical throughout the extraction and explanation processes. In the removal phase, maintaining the right pH helps in attaining effective sucrose extraction from the walking stick. Controlling the pH throughout information help in the precipitation of contaminations and non-sucrose elements, leading to a purer end product. Additionally, pH influences the task of enzymes involved in the failure of macromolecules, impacting the total efficiency of the procedure. By very carefully monitoring and changing the pH degrees at different processing actions, sugar cane processors can improve sugar recovery rates, minimize chemical use, and optimize the general manufacturing process. Effective pH control not just boosts the quality of the end product yet also adds to lasting and cost-effective sugar cane processing procedures.

Advanced Filtering Methods

Applying sophisticated purification techniques in sugar cane processing improves the effectiveness and purity of the final item via improved splitting up techniques. By integrating advanced filtration technologies, such as membrane layer purification and triggered carbon filtering, sugar cane handling plants can attain higher levels of sugar recuperation and boosted quality assurance.

Turned on carbon filtering is another advanced strategy that helps in the removal of colorants, off-flavors, and residual contaminations from sugar walking stick products. By utilizing turned on carbon's adsorption residential properties, this filtering method boosts the clearness and taste of the sugar, fulfilling the high requirements demanded by customers and market regulations.

Energy-Efficient Distillation Approaches

Energy-efficient distillation approaches are vital for maximizing the sugar walking stick handling industry's power visit their website consumption while preserving high-quality product criteria. Conventional purification processes can be energy-intensive, resulting in greater production expenses and ecological impacts (Cane Sugar Processing Chemicals). Carrying out energy-efficient purification methods, such as vacuum purification or molecular purification, can considerably lower power requirements while enhancing total process efficiency

Vacuum cleaner purification entails lowering the pressure within the purification system, which decreases the boiling factor of the liquid mix being processed. This decrease in boiling factor lowers the energy needed for vaporization, leading to power financial savings contrasted to conventional distillation techniques.

On the other hand, molecular purification makes use of brief course purification strategies under high vacuum cleaner conditions to separate compounds based on their molecular weight. This method is particularly efficient for heat-sensitive compounds, as it operates at lower temperatures, minimizing power intake and maintaining item top quality.

Verdict

Report this page